Understanding Industrial Vacuum Systems Parts

In today’s fast-paced industrial environment, the role of industrial vacuum systems cannot be overstated. These systems play a pivotal role in maintaining cleanliness, efficiency, and productivity across various sectors, including manufacturing, packaging, and food processing. In this comprehensive guide, we delve deep into industrial vacuum systems parts, exploring their functionality, types, and maintenance strategies to help businesses maximize their investment in this essential technology.

The Importance of Industrial Vacuum Systems

Industrial vacuum systems are designed to remove debris, dust, and particulate matter from production environments, thereby enhancing safety and efficiency. Here are some of the key benefits:

- Improved Air Quality: Regular vacuuming of workspaces ensures a healthier environment for employees.

- Increased Efficiency: A clean workspace allows for smoother operations and reduces equipment wear and tear.

- Compliance: Many industries are regulated; maintaining cleanliness helps companies comply with safety and health standards.

- Cost Savings: Investing in quality vacuum systems can lead to reduced downtime and maintenance costs over time.

Types of Industrial Vacuum Systems

Understanding the various types of industrial vacuum systems is crucial for businesses looking to choose the right equipment. Here are some common types:

1. Central Vacuum Systems

Central vacuum systems consist of a network of tubing connected to a central vacuum unit. This type of system is ideal for large facilities, providing efficient suction across extensive work areas.

2. Portable Vacuum Systems

Portable vacuum systems are versatile and can be moved easily from one location to another. They are perfect for tasks requiring mobility or for cleaning hard-to-reach areas.

3. Stationary Vacuum Systems

Stationary vacuums are fixed equipment designed for specific cleaning tasks, often connected to other machines in manufacturing processes to collect waste directly at the source.

Key Components of Industrial Vacuum Systems Parts

Every industrial vacuum system comprises several parts, each playing a vital role in its overall performance. Let’s explore these essential components:

1. Vacuum Pump

The vacuum pump is the heart of any industrial vacuum system. It creates a vacuum by removing air and other gases from the system. Various types of pumps include:

- Positive Displacement Pumps: These pumps operate by capturing a volume of air and displacing it.

- Rotary Vane Pumps: Known for their high efficiency, these pumps use vanes that slide in and out of a rotor.

- Diaphragm Pumps: Ideal for handling delicate materials, these pumps use a diaphragm that flexes to create suction.

2. Filtration System

The filtration system is crucial for ensuring that the vacuumed materials do not escape back into the air. A high-quality filtration system helps keep the workspace clean and safe. Key filtration types include:

- HEPA Filters: Highly efficient in trapping small particles, HEPA filters are essential in environments where air quality is critical.

- Cartridge Filters: Ideal for larger debris, cartridge filters can handle significant amounts of dust and particles.

3. Collection Containers

These containers hold the debris that the vacuum collects. Depending on the application, containers can vary in size and material. Common options include:

- Dust Bags: Many portable vacuum systems utilize disposable dust bags for easy disposal.

- Drum Collectors: For larger operations, steel drums are often used to hold significant amounts of waste.

4. Hoses and Attachments

The hoses and attachments enable the vacuum system to reach various areas and surfaces. An array of attachments can be used to handle different tasks, such as:

- Crevice Tools: Perfect for tight spaces.

- Floor Nozzles: Suitable for large floor areas.

- Brush Attachments: Ideal for picking up debris from carpets and upholstery.

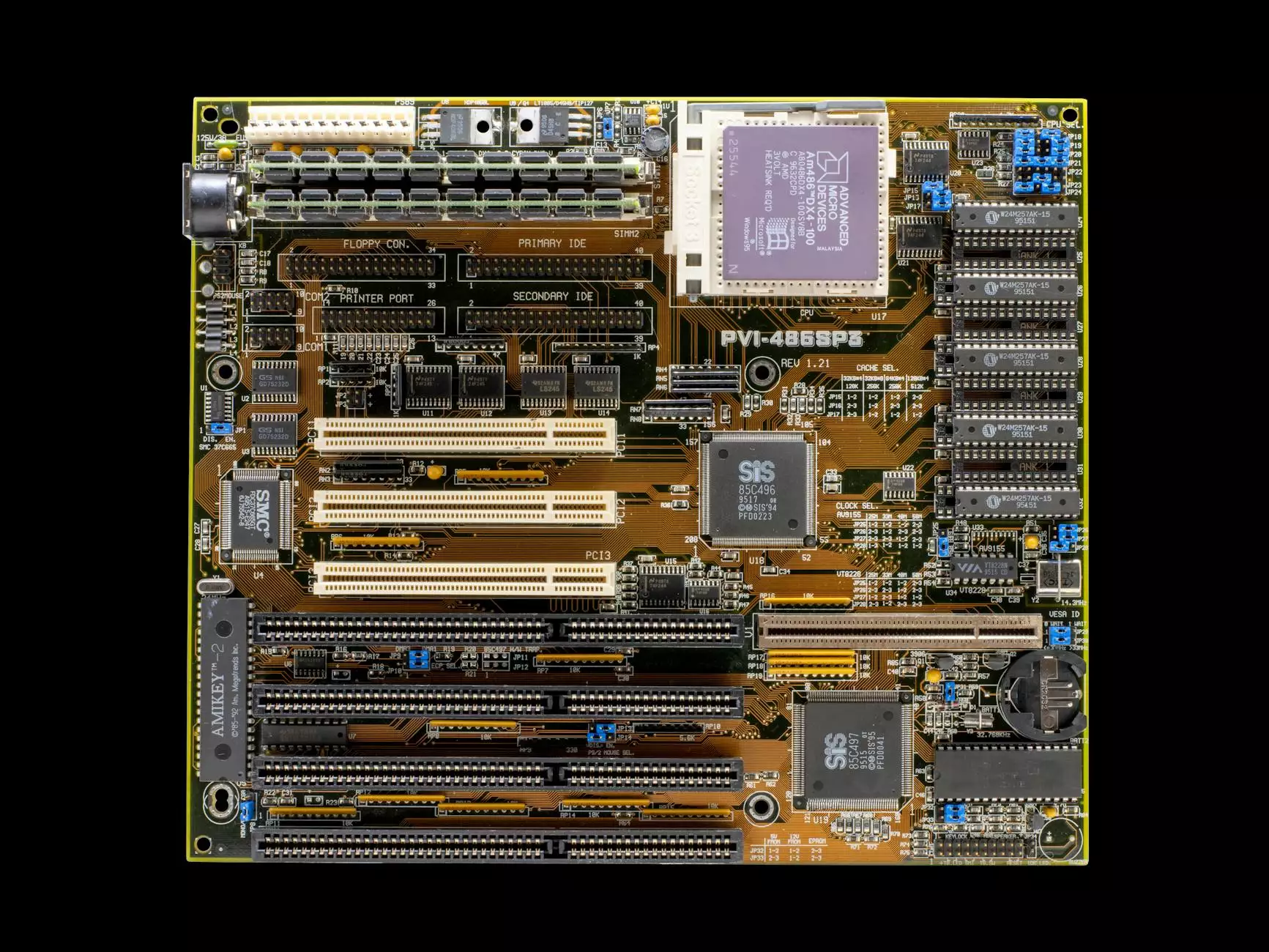

5. Control Panel

The control panel allows operators to manage the system's settings. Modern systems may feature advanced controls, including:

- Variable Speed Control: Adjusts the suction power based on the task at hand.

- Automatic Start/Stop Functions: Enhances efficiency by activating the system through sensors.

Choosing the Right Parts for Your Industrial Vacuum System

Selecting the right industrial vacuum systems parts is essential for ensuring optimal performance. Here’s what to consider:

1. Application Requirements

Analyze the specific tasks you intend to perform with your vacuum system. For heavy-duty operations, choose robust parts that can withstand constant use.

2. Compatibility

Ensure that all parts are compatible with your vacuum system. Mismatched components can lead to inefficiencies and increased wear.

3. Quality and Durability

Invest in high-quality parts that offer durability and longevity. It's often worth paying a bit more for parts that will last longer and require less frequent replacements.

4. Cost Considerations

While it’s important to be cost-effective, prioritize quality over price. Cheap parts can lead to breakdowns, ultimately costing more in repairs and replacements.

Maintenance Tips for Industrial Vacuum Systems

Regular maintenance of your vacuum system can lead to increased efficiency and extend its lifespan. Here are some essential maintenance tips:

1. Regular Cleaning

Keep the vacuum system clean, especially filters and hoses. A clogged filter can reduce suction power, while dirty hoses may lead to blockages.

2. Inspect Wear and Tear

Periodically check for signs of wear on components such as hoses and filters. Promptly replace any worn or damaged parts to prevent further issues.

3. Lubricate Moving Parts

For systems with moving parts, lubrication is key to performance. Ensure that all moving components are adequately lubricated to avoid friction and wear.

4. Schedule Professional Servicing

Consider scheduling professional inspections and servicing at regular intervals. Professionals can identify potential issues before they escalate, ensuring your systems run smoothly.

Conclusion

Understanding industrial vacuum systems parts and their functionality is crucial for any business seeking to optimize their operations. Investing in the right components and maintaining them correctly ensures that your industrial vacuum system remains efficient and effective. By keeping your work environments clean and compliant, you not only protect your employees but also enhance your operational efficiency. For further information, or to explore high-quality vacuum components, visit tmm.com.tr.